Mionix Mouse Scroll Wheel Repair

Today my mouse's scroll wheel finally gave out. It turned out to be an easy repair. There were two problems: the middle button wasn't consistently registering, and the scrolling action progressed from being loose to being almost completely decoupled. The mouse in question is a Mionix Avoir 7000 but the repair process might apply to any "prosumer" mouse. No new parts were needed.

Scroll Wheel Repair

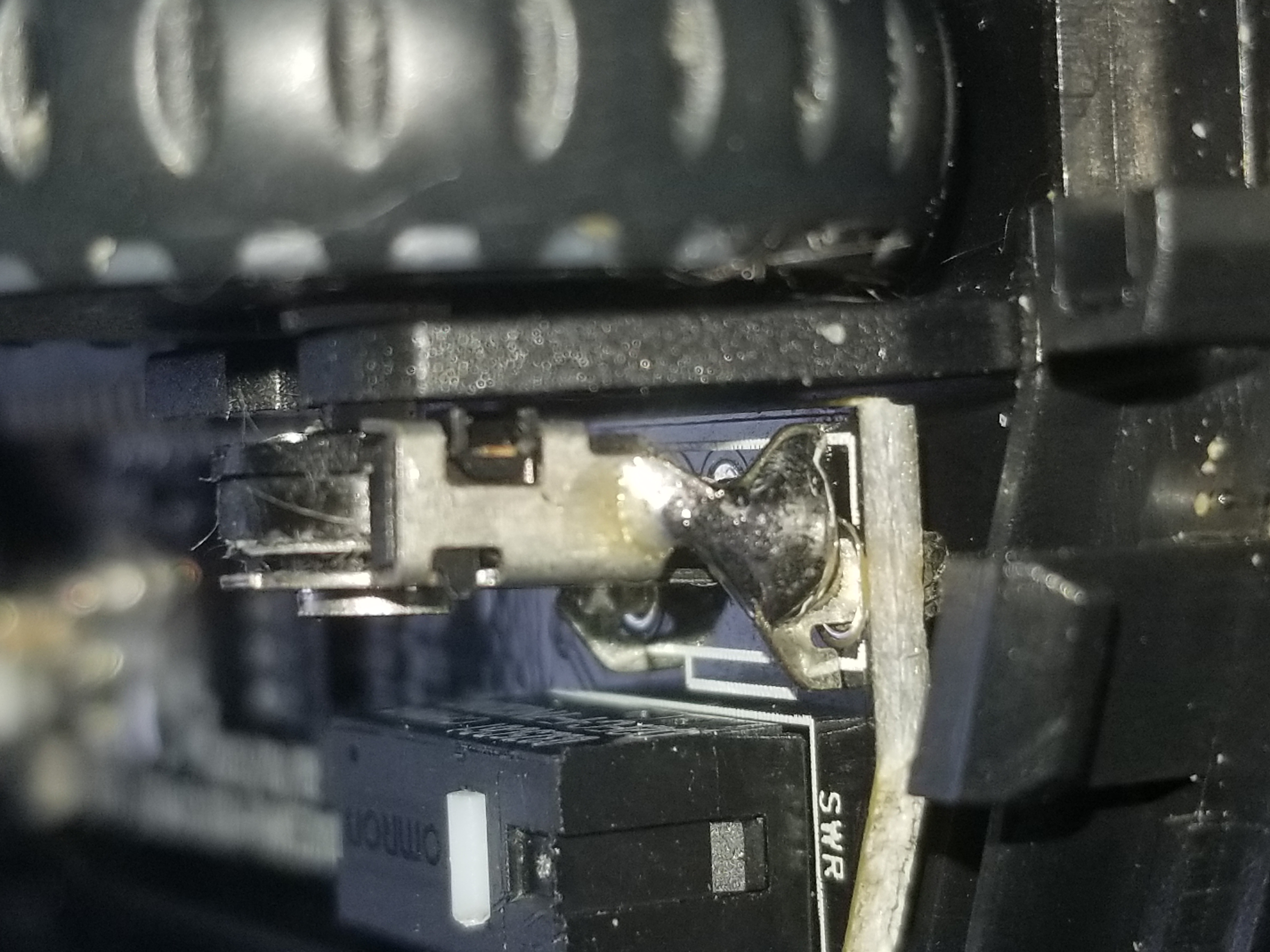

The scroll wheel is held in place by two plastic snap fits that are molded into the case. On its right, the wheel has a hex-shaped stud that fits into a rotary encoder with a corresponding hex-shaped slot. The stud was poorly designed - it wasn't long enough to fit fully into the encoder's slot and so it wasn't a tight fit. Because the scroll wheel's stud was able to move a tiny bit relative to the encoder's slot, it eventually rounded off and started skipping around inside the slot rather than actually working the encoder.

This was repairable because the hex stud had only rounded off at the tip, where it was engaged with the encoder. The stud still had ~2mm of length that wasn't worn down. The solution was therefore to move the encoder closer to the scroll wheel so it would engage with that part of the stud instead of the worn part. This involved cutting the encoder's rigid frame with some pliers and bending it forward. I then soldered the frame back together in its new position, which might not have been necessary but can't hurt.

It's possible this repair will last longer than the original as the stud was only barely inserted into the encoder to begin with. If the mouse were to be redesigned to either lengthen the stud or bring the optocoupler closer to the wheel (with associated PCB and frame changes), the scrolling action would work until the encoder gave out internally.

Middle Button Repair

I failed to take any good pictures of this repair. The scroll wheel has a cantilevered stud on its left that clicks a cheap snap-dome switches. These buttons always fail due to oxidation or pitting or accumulation of loose soot on the dome. To fix the button, open it and clean the tiny metal dome or its corresponding contact with isopropyl alcohol and an abrasive brush (or tweezers, or whatever). Most snap-dome switches - this one is no exception - have a cap that is held on by four plastic rivets. The switch can be opened by cutting the rivet heads with a razor and removing the cap. In this case the cap snapped right back into place, but I brushed on a little liquid rubber (red) to help keep it in place.